Develop biofabrication technologies

Develop current and new biofabrication technologies based on additive manufacturing, bioprinting, bio-assembly, and electrospinning.

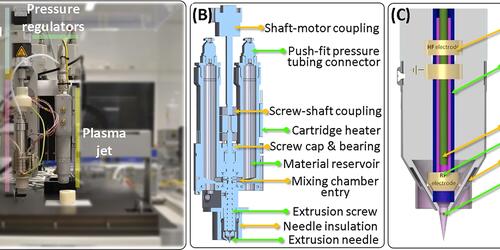

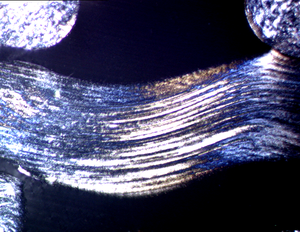

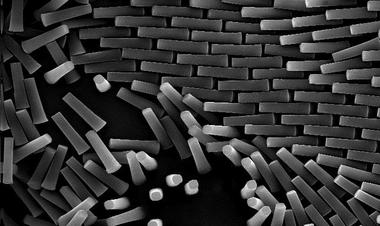

Among biofabrication technologies, bioprinting, additive manufacturing, bio-assembly, and spinning technologies form crucial clusters that shall be used for this purpose. These technologies will be further advanced in the future to include surface engineering methods during fabrication. Efforts focus on creating new printers and spinners that will enable a closer mimicry of native tissues architecture. The development of such technologies will also require new biomaterial chemistries.

Among biofabrication technologies, bioprinting, additive manufacturing, bio-assembly, and spinning technologies form crucial clusters that shall be used for this purpose. These technologies will be further advanced in the future to include surface engineering methods during fabrication. Efforts focus on creating new printers and spinners that will enable a closer mimicry of native tissues architecture. The development of such technologies will also require new biomaterial chemistries.

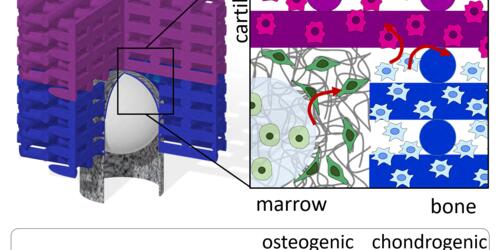

Technologies will be developed in a modular manner, so that specific mechanical, physico-chemical, and biological cues can be spatiotemporally displayed at the macro, micro, and nano scales in a controlled manner and in a predetermined anatomically functional 3D volume, since it has been shown that 3D cultures cell systems approximate better the native physiology and cellular response than 2D conventional systems.

Such technological development is expected to exceed current capabilities and allows for the fabrication of tissue constructs with a degree of mimicry that more closely matches native tissues and organs. Furthermore, new biofabrication technologies should be able to process new biomaterial (bioinks) formulations that are being continuously developed. These bioinks are engineered to more closely mimic local nutrient and signaling exchange at the interface between cells and extracellular matrix (ECM), while maintaining sufficient mechanical stability and the capacity to remodel as the tissue matures.

Such technological development is expected to exceed current capabilities and allows for the fabrication of tissue constructs with a degree of mimicry that more closely matches native tissues and organs. Furthermore, new biofabrication technologies should be able to process new biomaterial (bioinks) formulations that are being continuously developed. These bioinks are engineered to more closely mimic local nutrient and signaling exchange at the interface between cells and extracellular matrix (ECM), while maintaining sufficient mechanical stability and the capacity to remodel as the tissue matures.

Researchers involved in this project

Carlos Mota, Paul Wieringa, Jiaping Li, Matt Baker, Rong Wang, Andrea Calore, Vahid Ansari.

Related publications

van Kampen K, Olaret E, Stancu IC, Campos DD, Fischer H, Mota C, Moroni L. Hypotrochoidal scaffolds for cartilage regeneration. Materials Today Bio 2023; 23:100830.

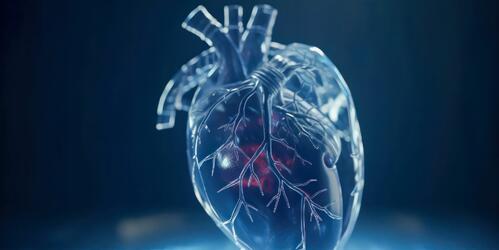

Download PubblicationTabury K, Rehnberg E, Baselet B, Baatout S, Moroni L. Bioprinting of Cardiac Tissue in Space: Where Are We?. Adv Healthc Mater 2023; 12(23): 2203338

Download PubblicationKuhnt T, Camarero‐Espinosa S, Takhsha Ghahfarokhi M, Arreguín M, Cabassi R, Albertini F, Nieto D, Baker MB, Moroni L. 4D printed shape morphing biocompatible materials based on anisotropic ferromagnetic nanoparticles. Adv Funct Mater 2023; 32(50):2202539.

Download PubblicationCamarero-Espinosa S, Moroni L. Janus 3D printed dynamic scaffolds for nanovibration-driven bone regeneration. Nature Comm 2021; 12(1): 1031

Download PubblicationSinha R, Cámara-Torres M, Scopece P, Verga Falzacappa E, Patelli A, Moroni L, Mota C. A hybrid additive manufacturing platform to create bulk and surface composition gradients on scaffolds for tissue regeneration. Nature Comm 2021; 12(1): 530.

Download PubblicationCamarero‐Espinosa S, Beeren I, Liu H, Gomes DB, Zonderland J, Lourenço AFH, van Beurden D, Peters M, Koper D, Emans P, Kessler P, Rademakers T, Baker MB, Bouvy N, Moroni L. 3D Niche‐Inspired Scaffolds as A Stem Cell Delivery System for The Regeneration of The Osteochondral Interface. Advanced Materials 2024; 16(1): 2310258.

Download PubblicationGaharwar AK, Mihalia SM, Kulkarni AA, Patel A, Di lUca A, Reis RL, Gomes ME, van Blitterswijk C, Moroni L, Khademhosseini A. Amphiphilic beads as depots for sustained drug release integrated into fibrillar scaffolds. J Control Release 2014, 10(187): 66-73.

Download PubblicationLeferink A, Schipper D, Arts E, Vrij E, Rivron N, Karperien M, Mittmann K, van Blitterswijk C, Moroni L*, Truckenmüller R*. Engineered Micro-Objects as Scaffolding Elements in Cellular Building Blocks for Bottom-Up Tissue Engineering Approaches. Advanced Materials 2014, 26(16): 2592-9.

Download Pubblication-

Higuera GA, Hendriks JAA, van Dalum J, Wu L, Schotel R, Moreira-Texeira L, Leijten JCH, van den Doel M, Karperien M, Riesle J, van Blitterswijk CA, Moroni L. Screening in vivo of extracellular matrix components produced by multiple experimental conditions implanted in one animal. Integrative Biology 2013, 5(6): 889-98.

Download Pubblication Nandakumar A, Truckenmueller RK, Ahmed M, Damanik F, Santos DR, Aufferman N, Habibovic P, van Blitterswijk C, Moroni L. A fast process for imprinting micro- and nanopatterns on electrospun fiber meshes at physiological temperatures. Small 2013; 9(20:3405-9.

Download Pubblication-

Fedorovich NE, Swennen I, Girones J, Moroni L, van Blitterswijk CA, Schacht E, Alblas J, Dhert WJ. Evaluation of photocrosslinked lutrol hydrogel for tissue printing applications. Biomacromolecules 2009; 10(7): 1689-96.

Download Pubblication Moroni L, Schotel R, de Wijn JR, van Blitterswijk CA. 3D Fiber Deposited-Electrospun Integrated Scaffolds Enhances Cartilage Tissue Formation. Adv Funct Mater 2008;18(1): 53-60.

Download PubblicationMoroni L, van Blitterswijk CA. Converge and regenerate. Nat Mater 2006;5(6):437-8.

Download PubblicationChakraborty J, Fernandez-Perez J, Takhsha Ghahfarokhi M, van Kampen KA, ten Brink T, Ramis J, Kalogeropoulou M, Cabassi R, de Julián Fernández C, Albertin F, Mota C, Ghosh S, Moroni L. Development of 4D-bioprinted shape-morphing magnetic constructs for cartilage regeneration using a silk fibroin-gelatin bioink. Cell Reports Physical Science 2024; 2(6)

Download Pubblication