News & Events

Kick-off of FAST at MERLN

Category: Group Activities

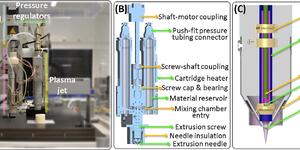

Eight European companies and research institutes have teamed up in the EU-funded research and innovation project “FAST”, which stands for “Functionally graded Additive Manufacturing (AM) scaffolds by hybrid manufacturing”, to make a new 3D printing technology available for the manufacture of implants customized to the patient at affordable cost. Specific patient implants can promote effective preoperative planning, shortening the time of surgery and improving the lifetime of the implant.

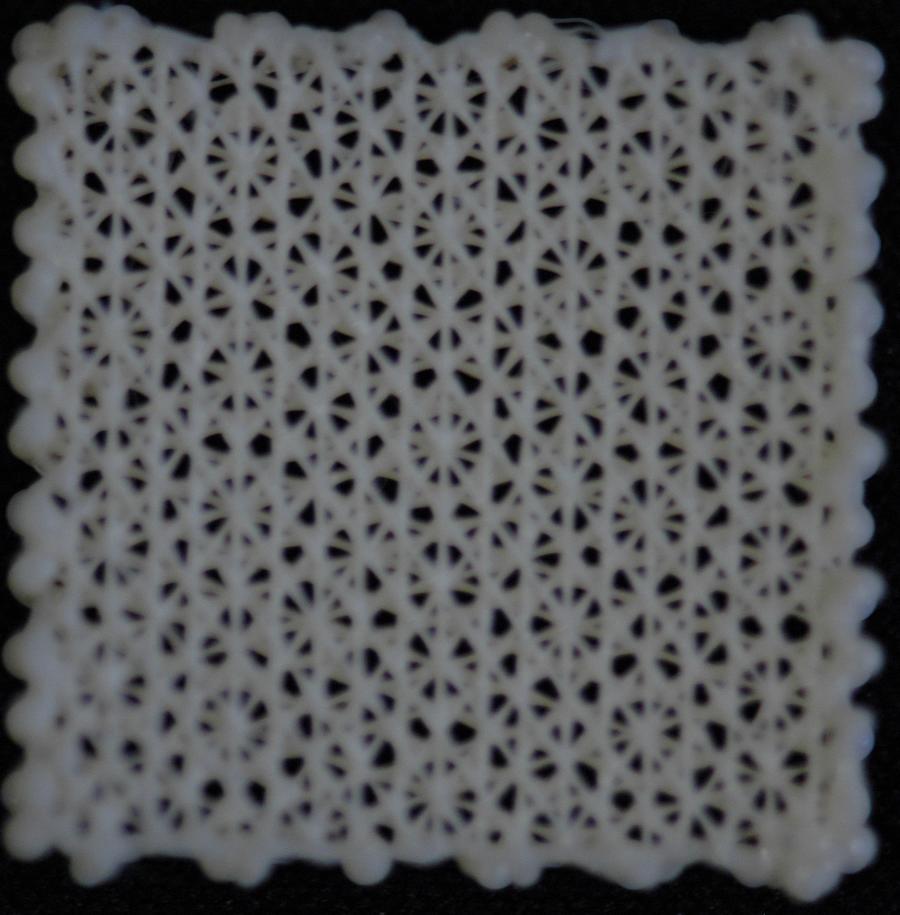

The medical sector is now the fourth industrial sector using Additive Manufacturing. Compared to traditional methods, this technology has the capabilities to produce time and cost-efficiently customised surgical and prosthetic devices, surgical implants and scaffolds for tissue regeneration individually for each single patient. Scaffolds production for tissue regeneration is one of the main fields where the “Design for Function” feature of AM makes the difference relative to the other production techniques, in particular if in the production process all the needed “functions” can be introduced: shape and porosity, mechanical stability and biochemical properties such as cell growth control or antibiotic function. The FAST project aims to develop a cost-efficient technology to integrate all these “functions” in a single AM process that is even capable to produce gradients in the bulk or surface properties of the individual scaffold.

Thus not only customized shapes of scaffolds can be produced, but also bulk and surface properties of the scaffold material can be tailored according to the specific needs of each individual patient. In practice this will translate into improved tissue ingrowth and regeneration properties combined with higher structural stability of implants. Furthermore, the incorporation of smart fillers with bio-active properties into the scaffold material will reduce the risk of post-surgery infections. Thus, the FAST technology has the potential to increase the patients’ comfort at an affordable cost for them and the healthcare system. The project will demonstrate its developments in a small pilot production of scaffolds for bone regeneration to be tested in a pilot in vivo trial.

For more information, please visit: http://project-fast.eu/en/home