News & Events

Gradient Scaffolds

Category: Events

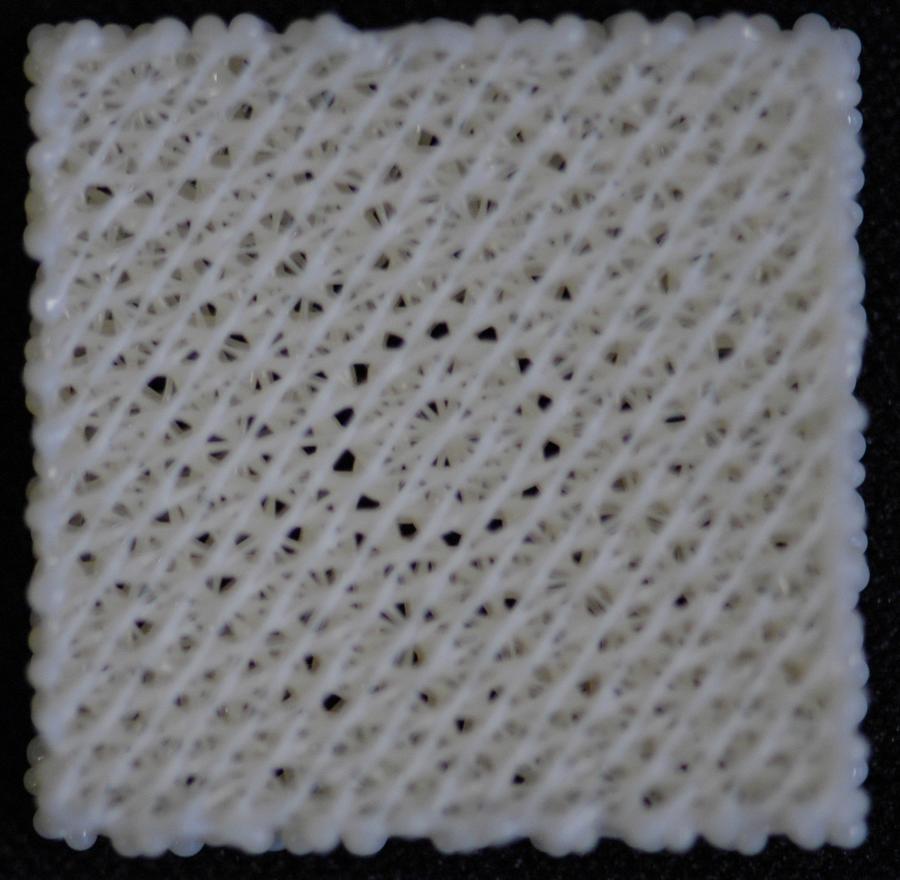

Structural as well as physico-chemical gradients can be considered as an additional element in designing scaffolds for stem cell-based regenerative medicine applications. In a few recently published papers, the Moroni Lab has shown how gradients in pore size and shape could aid in the differentiation of bone marrow derived adult mesenchymal stem (or stromal) cells towards skeletal lineages. When MSCs are cultured in scaffolds with pores varying in size, they can be better differentiated towards osteoblasts or chondrocytes in presence of either chondrogenic or osteogenic media. Specifically with increasing pore size, better osteogenic differentiation occurs. Vice versa, with decreasing pore size, better chondrogeneiss is observed. Similarly, when pore shape is varied from squared to increasingly rhomboidal shapes, MSCs shift their differentiation preference from the chondrogenic to the osteogenic lineage, respectively. Such influence on stem cell differentiation seems to be connected to different local nutrient availability, as shown by a differential expression of hypoxic inducible factors.

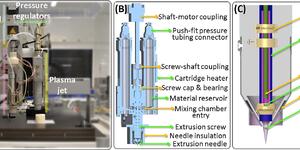

Following a similar, but different approach, 3D scaffolds with discrete gradients in surface energy or stiffness were also created and evaluated for the same purpose. Such gradients were created by changing the deposition order of commonly used biodegradable biomaterials in the field of regenerative medicine, such as poly(lactic acid), poly(carpolactone) and polyactive. Whereas stiffness gradients didn't contribute to a net increase in MSCs differentiation, surface energy gradients did. The net effect of such gradients should be decoupled by the intrinsic variation in polymer chemistry, which also occurred during additive manufacturing of these 3 different polymers in different sequences. Nonetheless, physico-chemical gradients created by multi-material additive manufacturing could be an appealing strategy to follow in designing and fabricating scaffolds for skeletal regeneration.

These studies show new avenues in the ever growing biofabrication field, where additive manufacturing of hierarchical scaffolds promises to be a new exciting bioprinting strategy.