News & Events

Biofabrication with dynamic materials

More News

Integrating Biofabrication Technologies

Unlocking the secrets of osteochondral regeneration has long been a daunting challenge, with the intricate interplay between cartilage and bone presenting formidable hurdles. However, a groundbreaking approach is on the horizon, poised to redefine the landscape of tissue regeneration: multiphasic scaffolds – the cornerstone of cutting-edge strategies aimed at mirroring the complexities of the osteochondral unit and nurturing the growth of implanted bone-marrow derived stem cells (BMSCs). Yet, amidst the promise, hurdles remain. Stem cell loss during expansion in vitro and the limited control over their behavior within scaffolds both in vitro and in vivo pose formidable challenges.

Read More

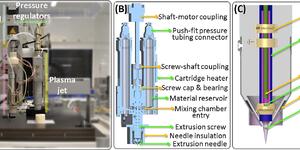

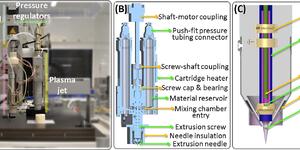

Bioprinting in Space

In a new Pathfinder Open project, PULSE, we have partnered with different experts in space technology and use thereof to study how the Space environment could be working as an accelerator of ageing…

Read More

New Hybrid Biofabrication technology

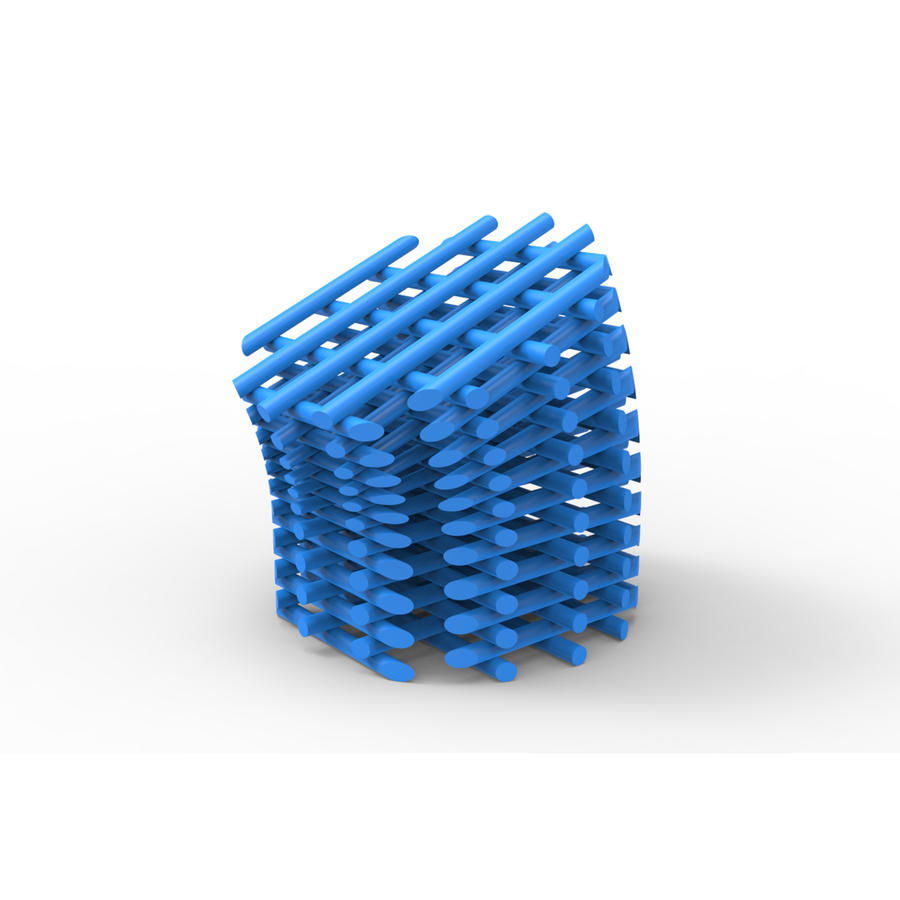

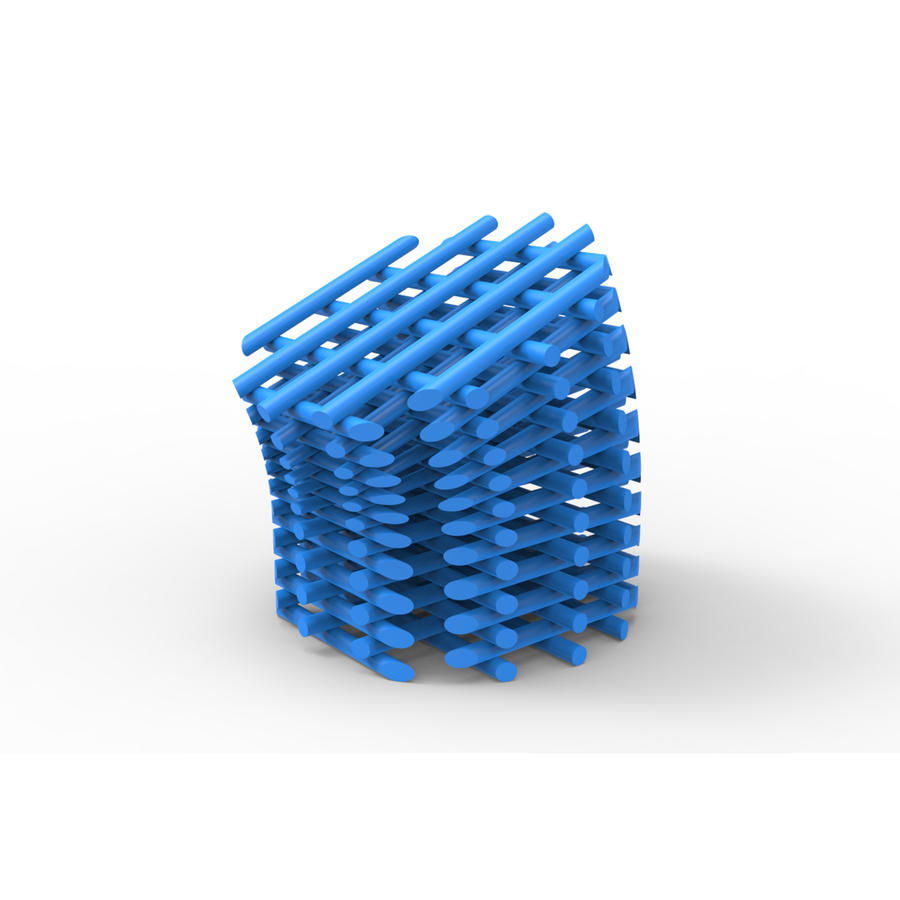

Many tissues in our body display gradients. These are not only biological gradients, but also structural, physical, and chemical ones, resulting in smoother variations of mechanical properties and cell functional activity.

Read More

Kidney 3D in vitro models through bioprinting

At the Complex Tissue Regeneration department, we work hard to bridge the gap towards the dream of organs bioprinting. Step by step, we are now progressing towards understanding more and more in depth the requirements to bioprint different kidney cells, either derived from pluripotent stem cells or of adult species.

Read More

Bioprinting through Levitation

Magnetic levitation offers the possibility to place cells in a precise position in space through controlling the magnetic forces applied to magnetized cells. This new biofabrication technique, at the interface between bioprinting and bioassembly, provides new ways to create large-scale biological constructs that can be used for regenerative medicine purposes.

Read More

Published on: August 15, 2018

Category: Events

The awarded project focuses on the development of new polymeric materials and hydrogels based on dynamic chemical bonds that ensure that the materials react to different conditions during processing. This allows optimal properties of the 3D-printed product to be obtained. In addition, end products can also be made with switchable properties. The project is a collaboration between Eindhoven University of Technology, Maastricht University, DSM, Xilloc and Brightlands Materials Center (BMC), a public-private research center in which scientists and industry specialists work together on sustainable technological innovations in the field of polymer materials.

To know more:

https://www.brightlandsmaterialscenter.com/brightlands-materials-center-kicks-off-unique-project-developing-innovative-materials-for-additive-manufacturing-and-4d-printing/